Image 1 of 3

Image 1 of 3

Image 2 of 3

Image 2 of 3

Image 3 of 3

Image 3 of 3

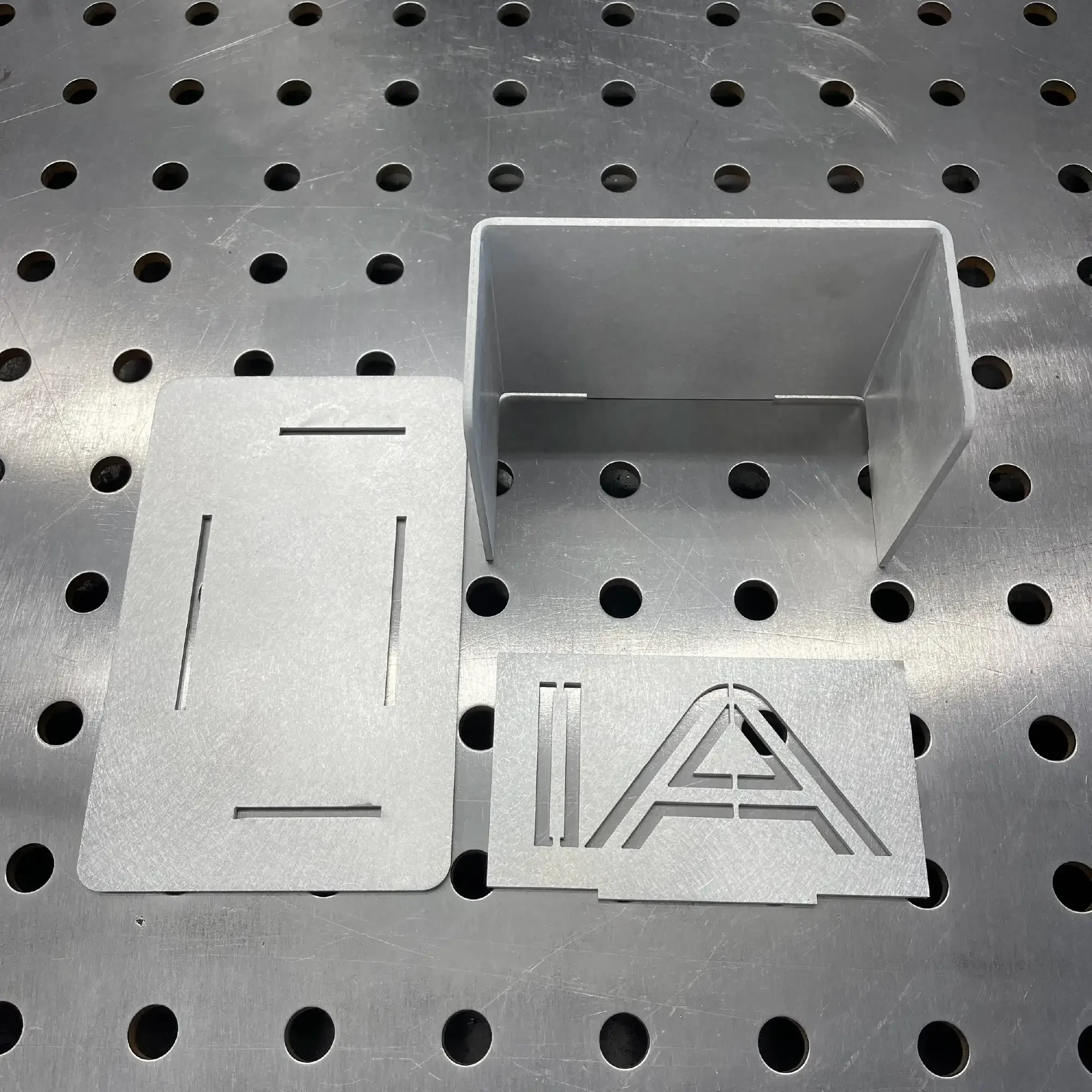

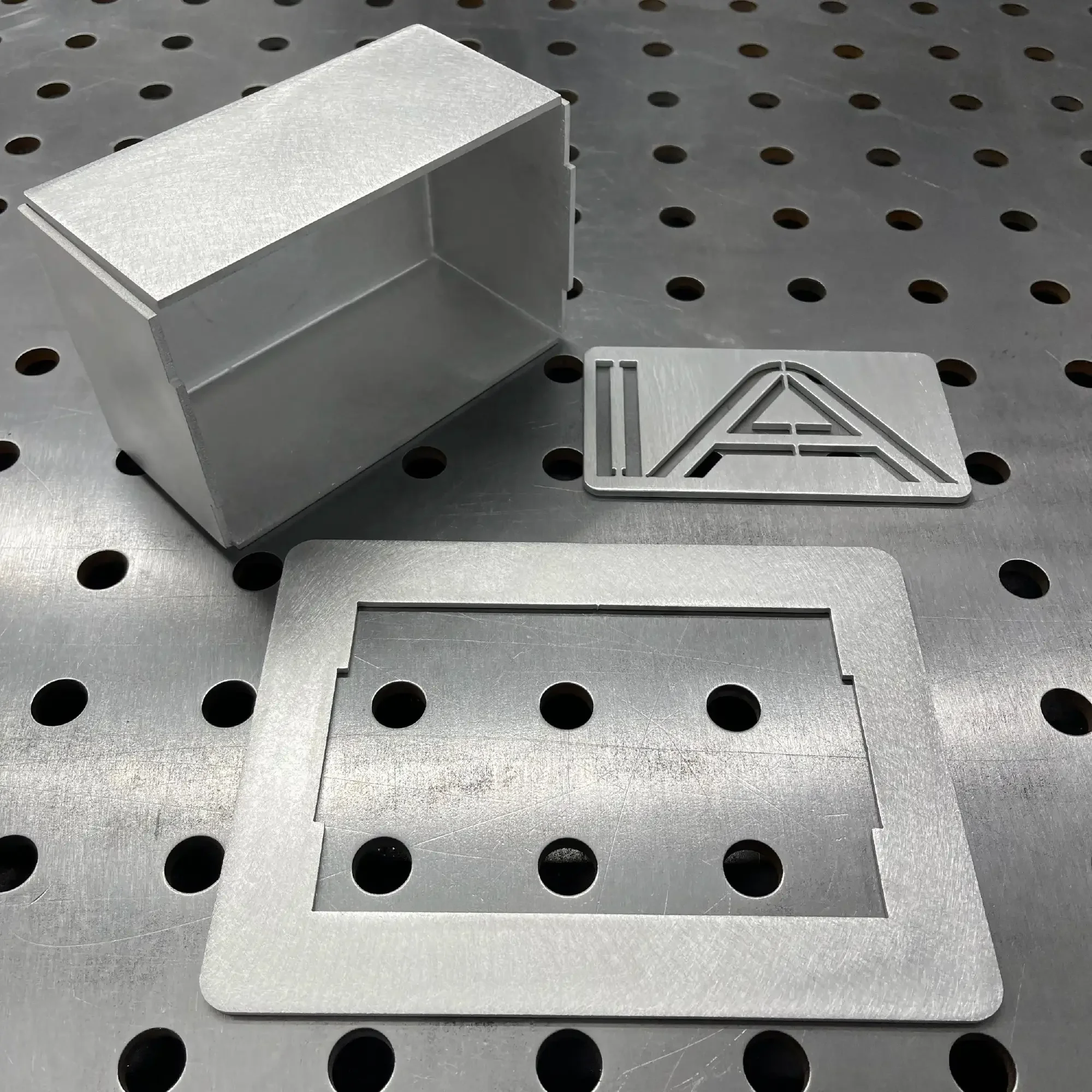

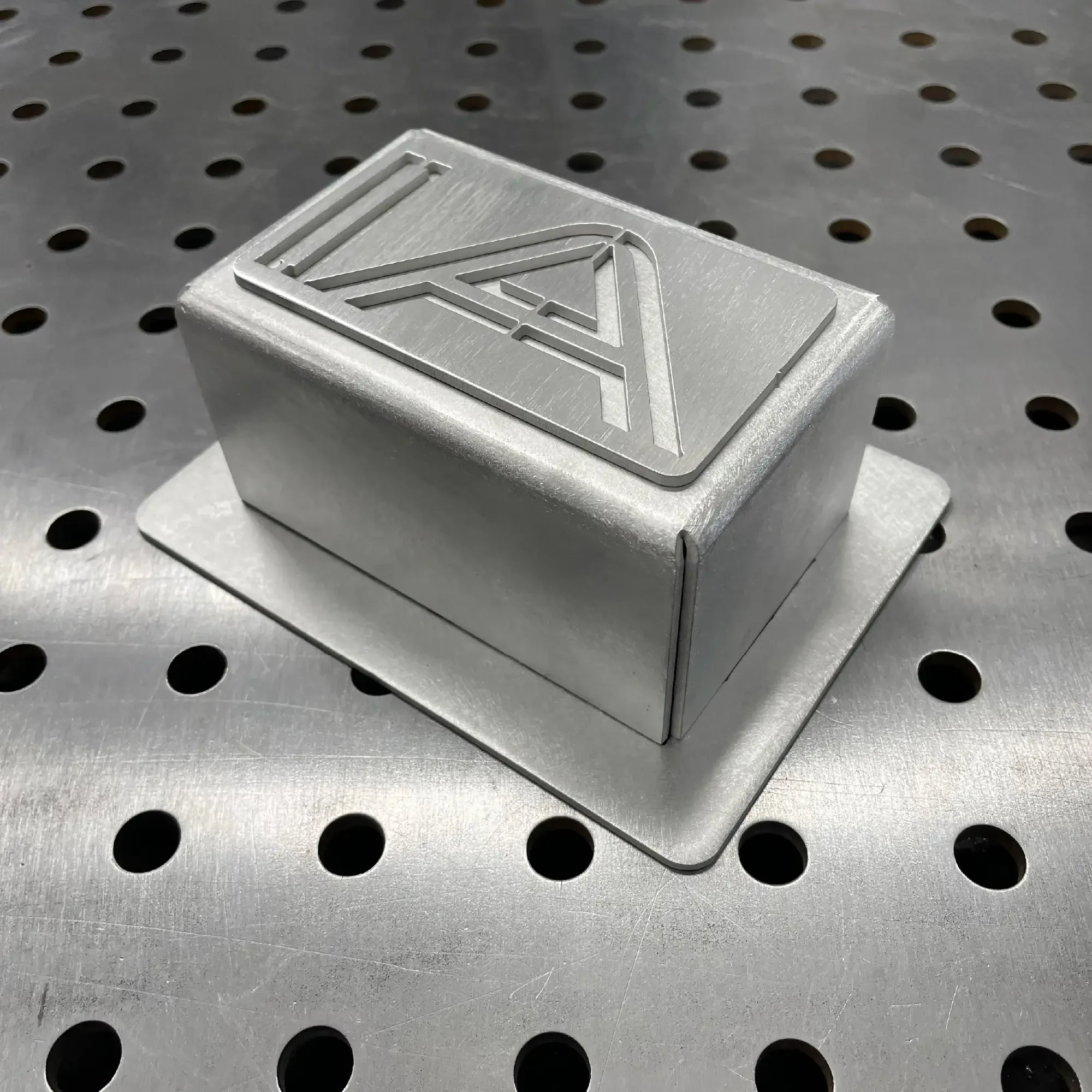

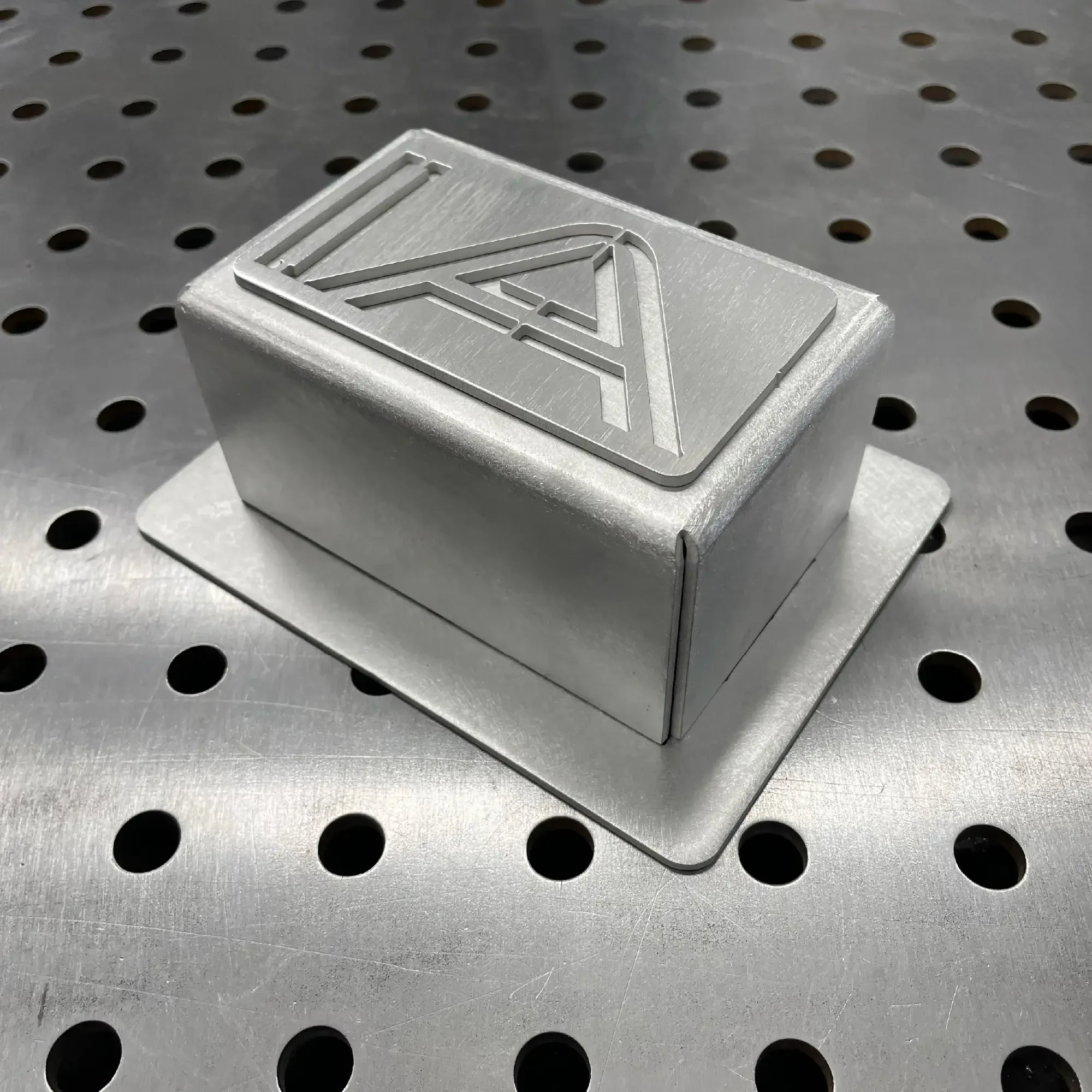

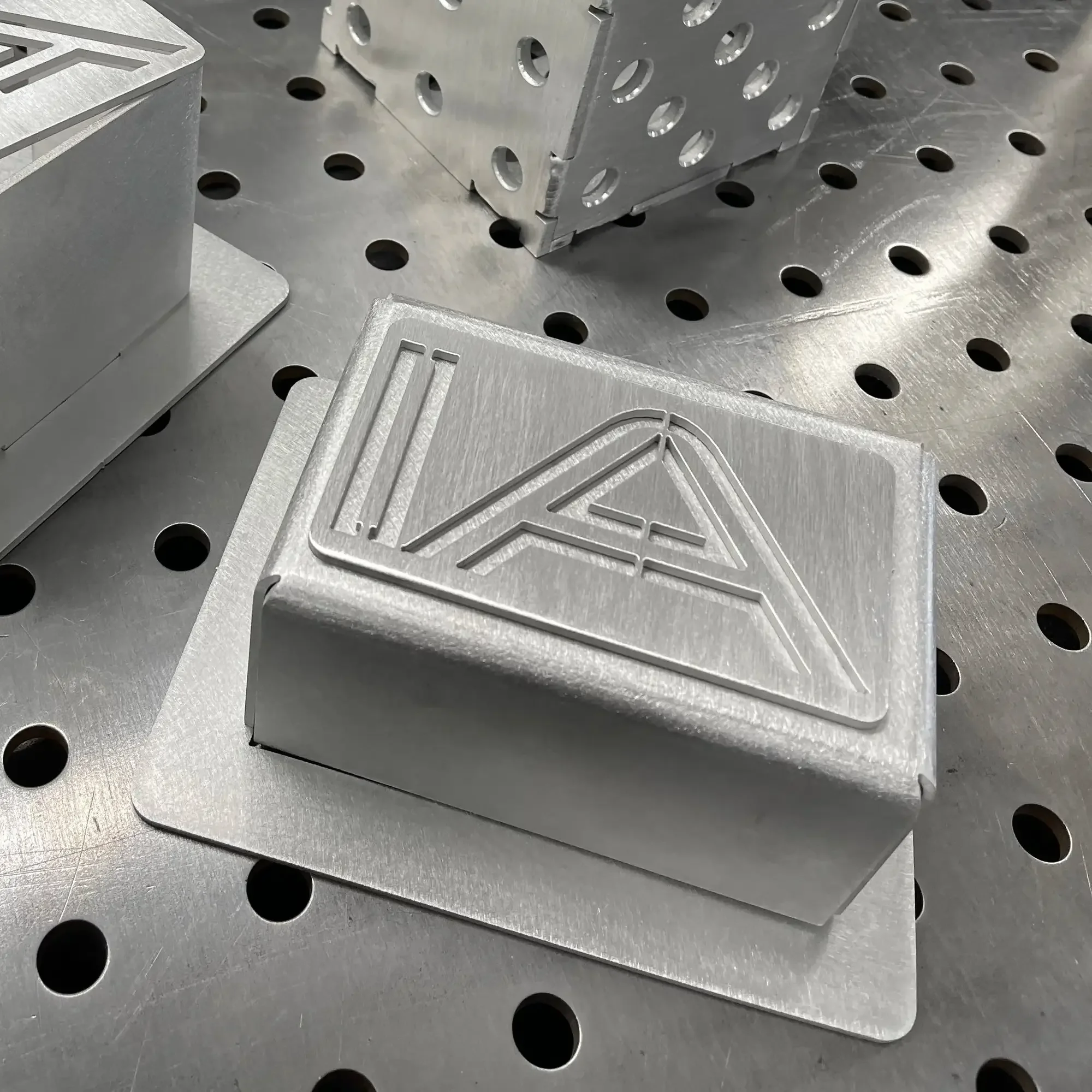

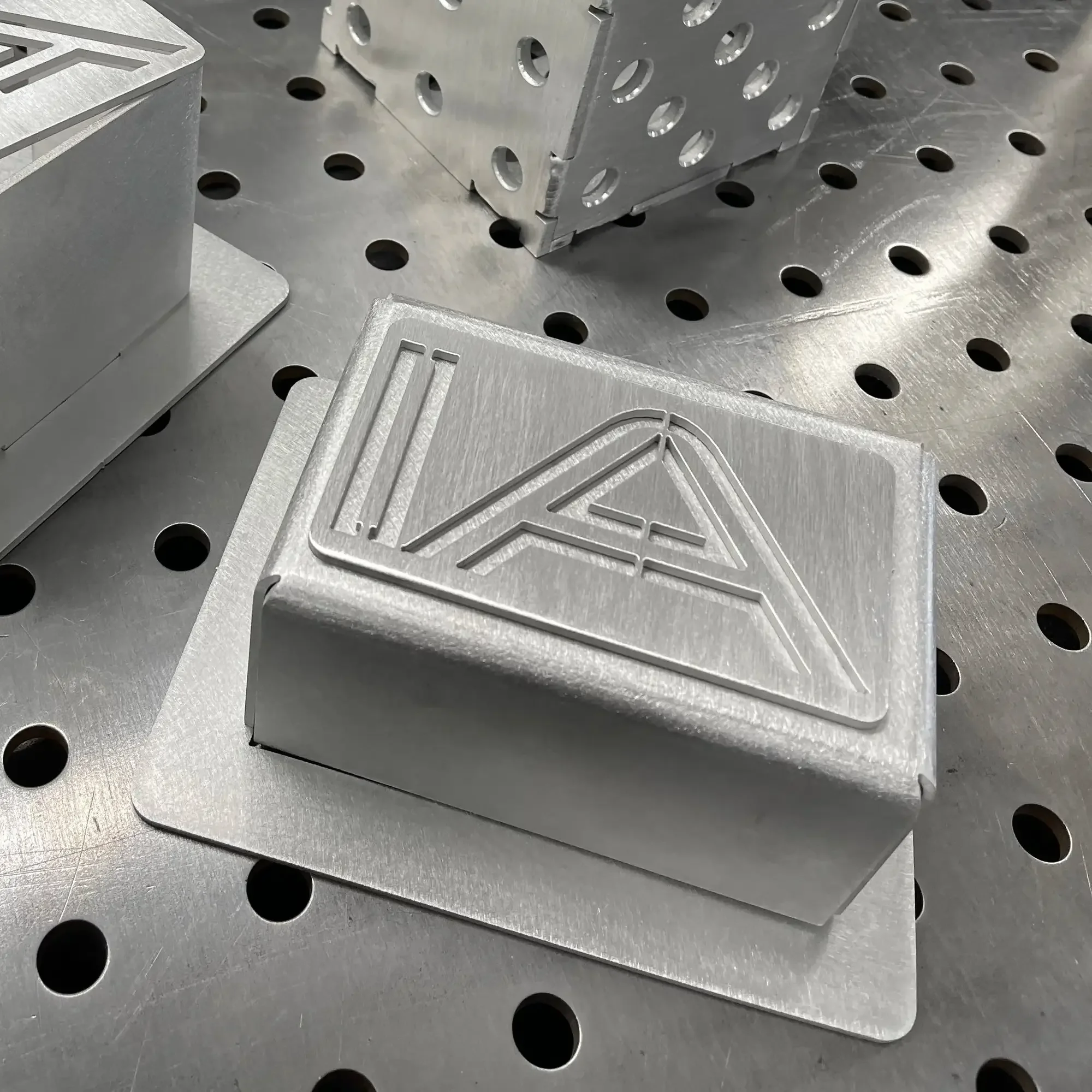

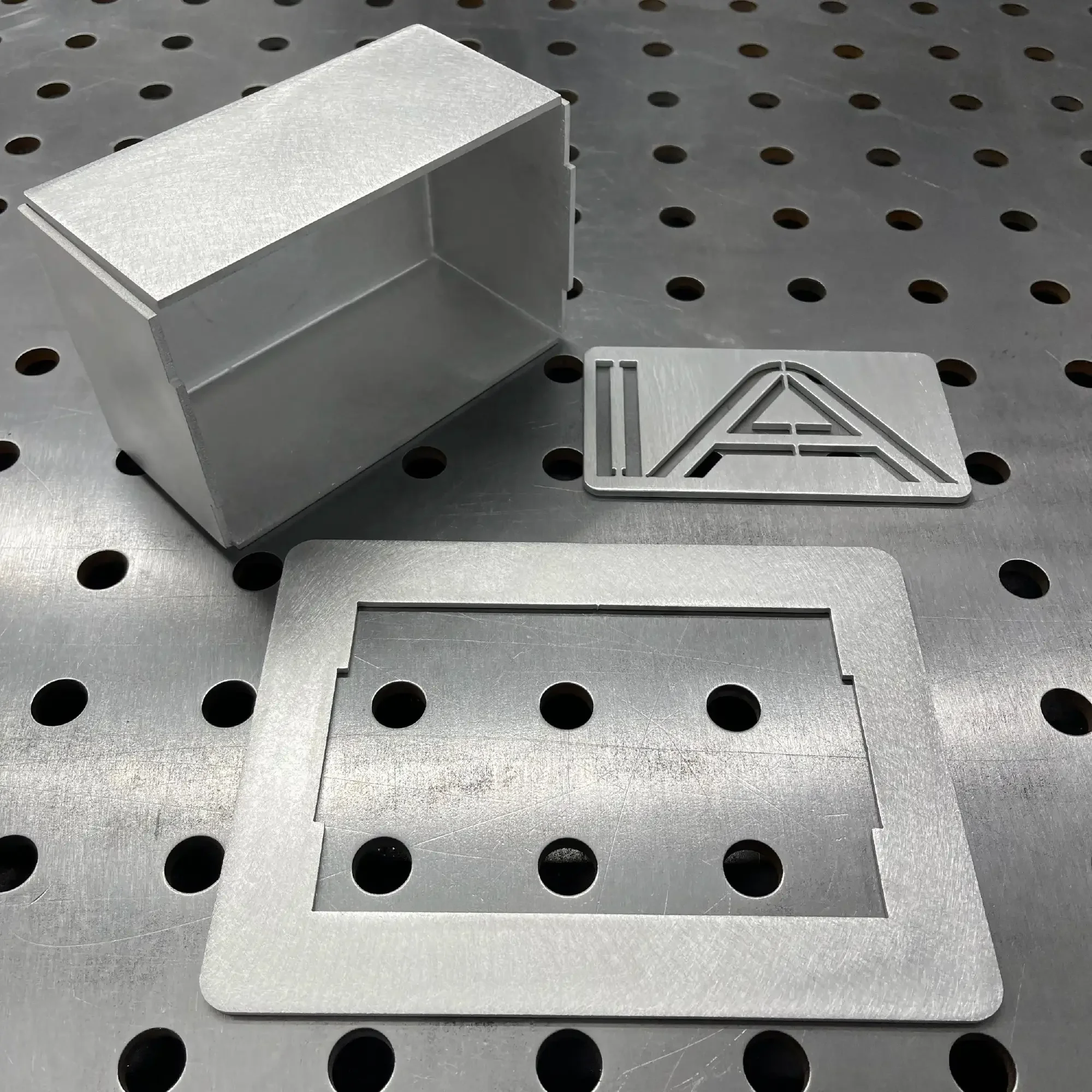

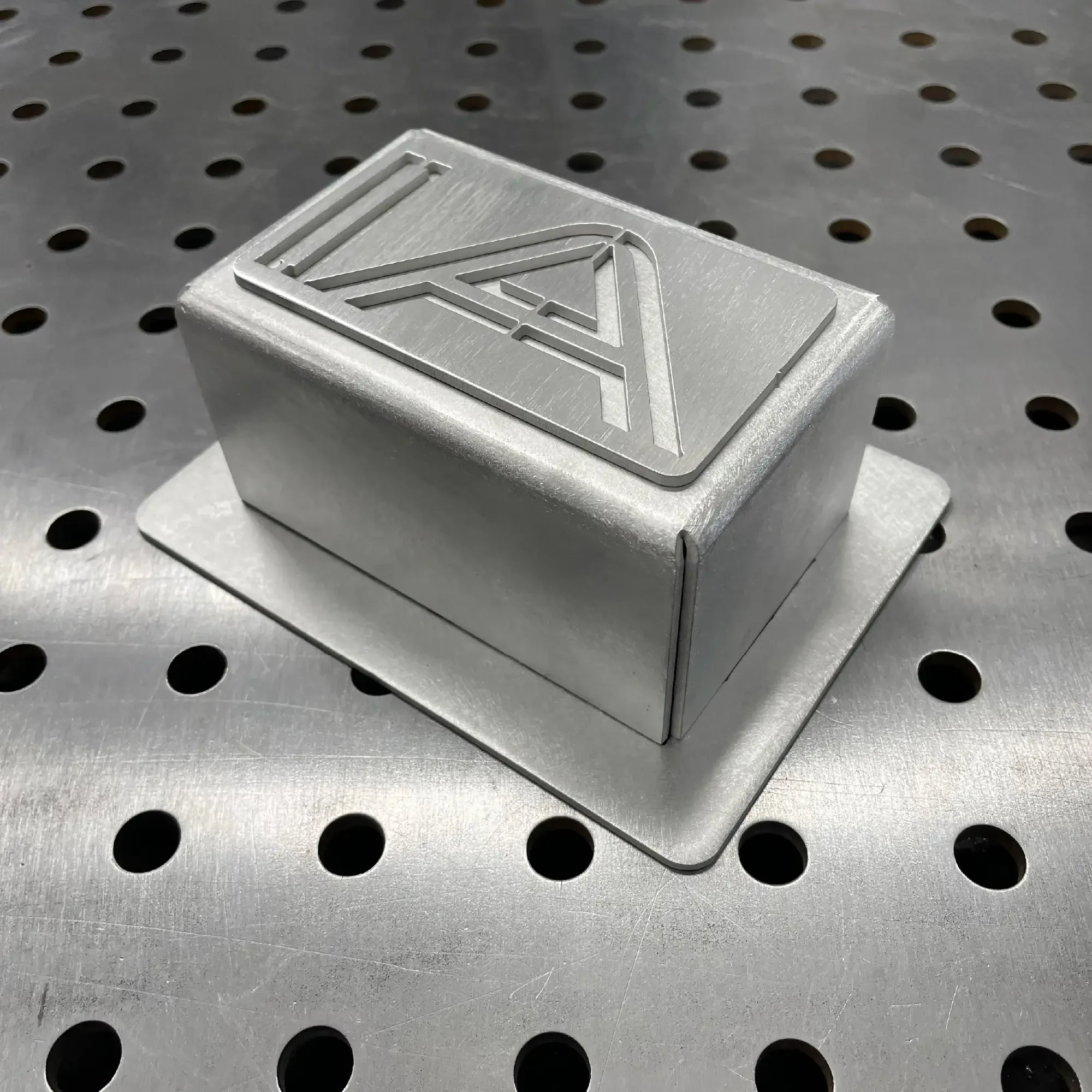

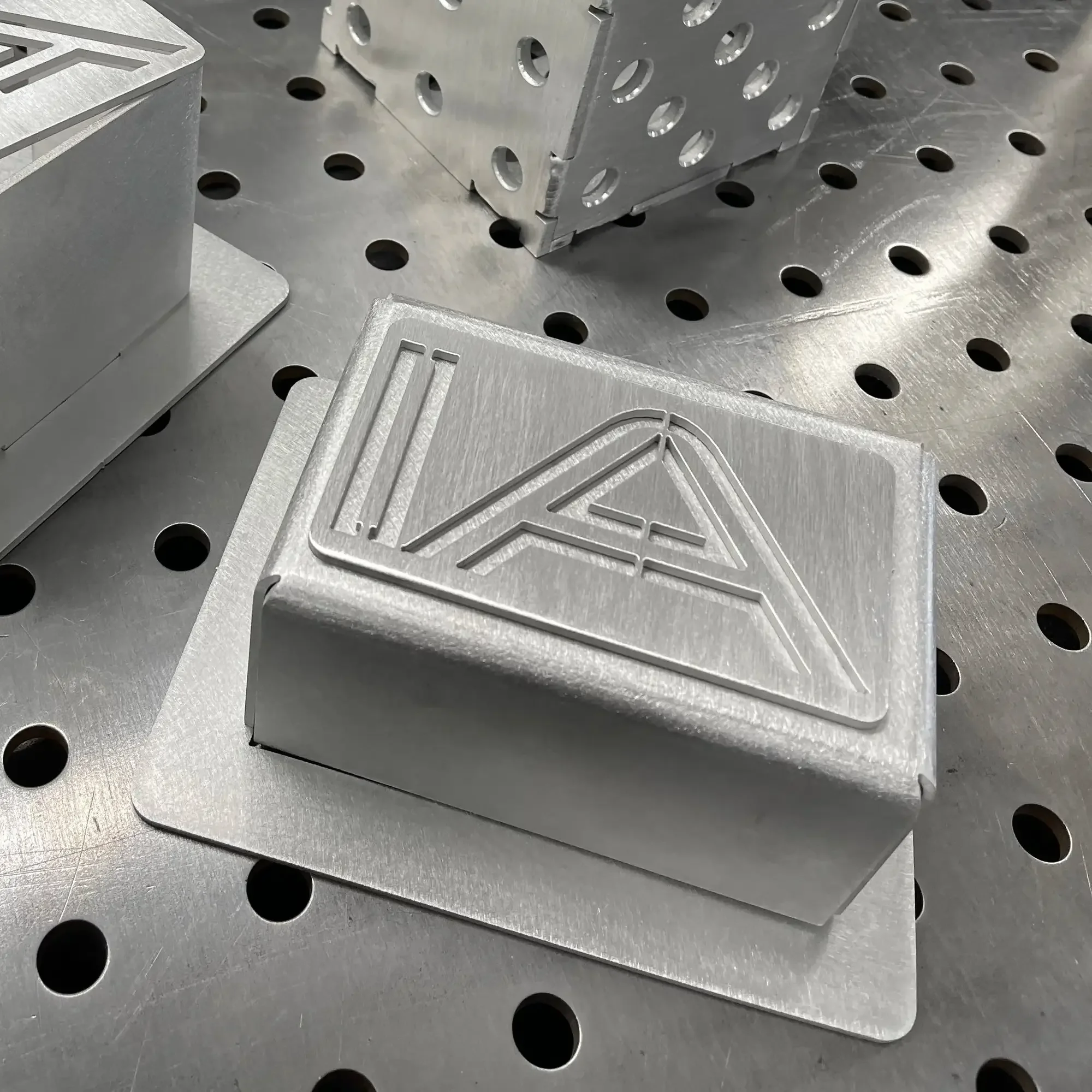

Aluminium TIG Practice KIT-3 Box It Up

Build precision, manage heat, and master box welds.

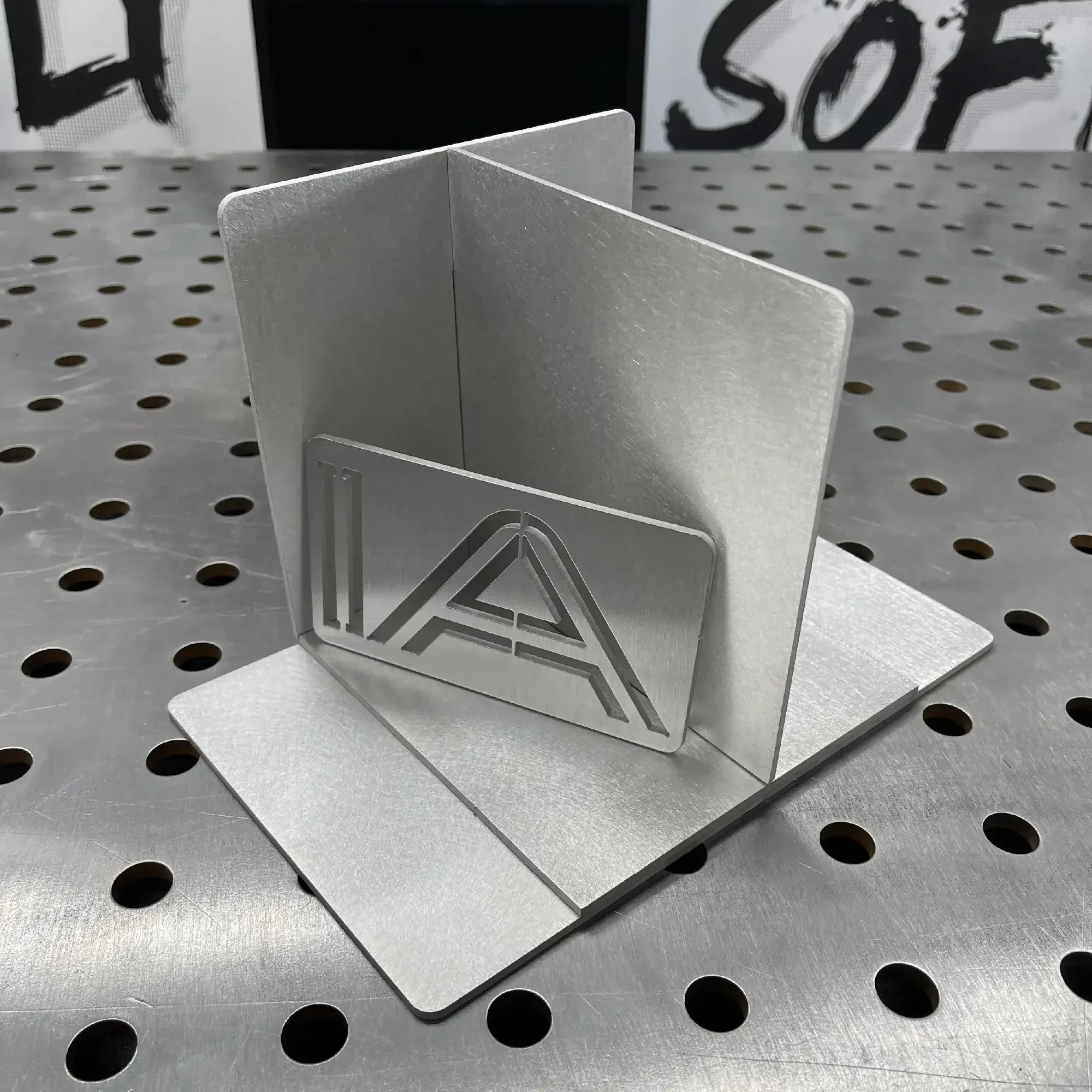

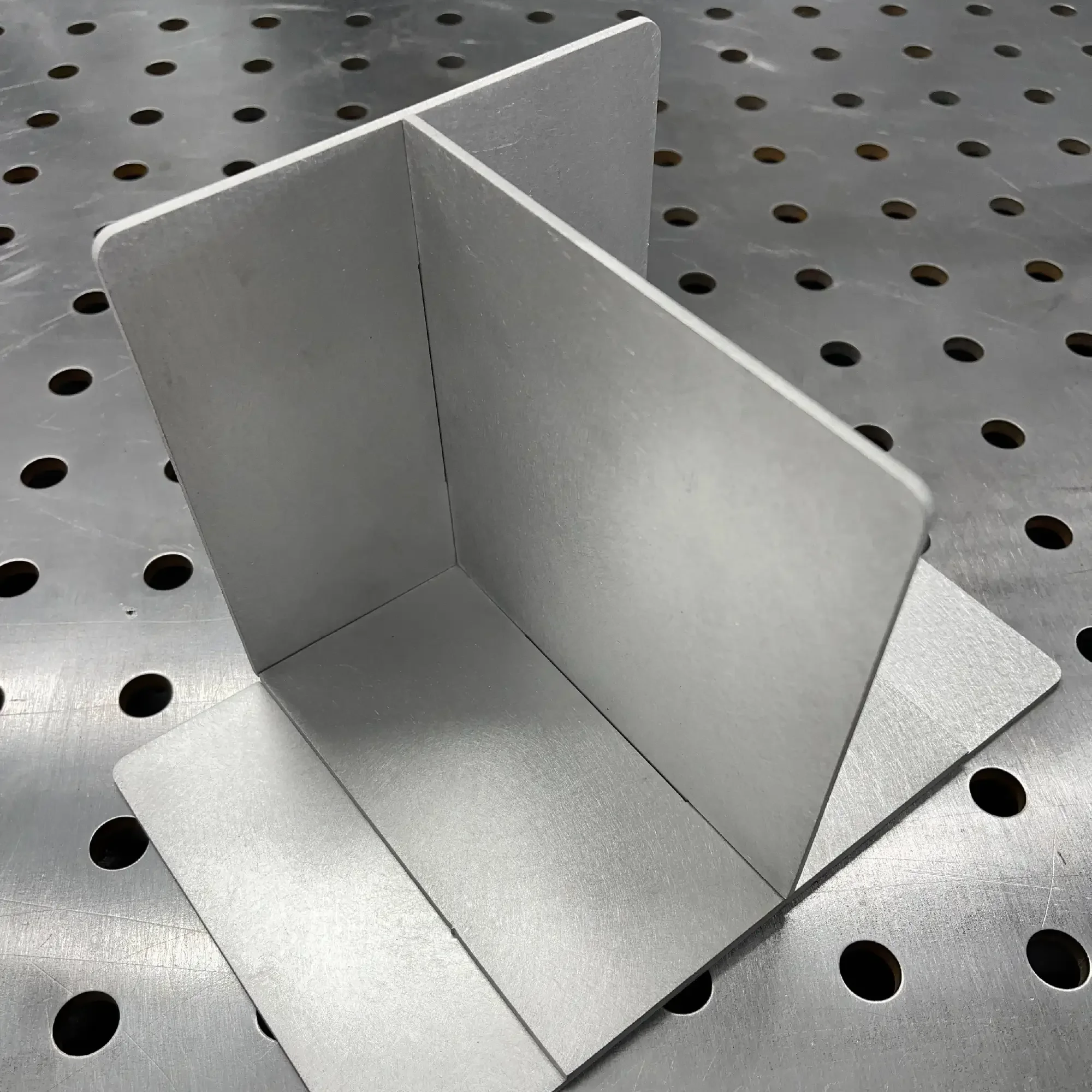

The IA-FAB Aluminium TIG Practice KIT-3 “Box It Up” is built to challenge and refine your control on closed and open-corner TIG joints. This precision laser-cut kit is designed for training on real-world aluminium box weld setups, giving you the chance to fine-tune your torch angle, filler rhythm, and distortion management.

Cut from 0.125” (3.2 mm) 5052-H32 aluminium sheet metal, each piece fits perfectly for repeatable practice and consistent setup. The “Box It Up” kit helps you dial in bead consistency and learn proper cooling control — crucial for aluminium TIG work.

Specs

Material: 0.125” (3.2 mm) 5052-H32 aluminium

Recommended filler: 3/32” 4043

Joints: Fillet, open corner

Focus: Box joint welding, tie-ins, distortion control, and fit-up accuracy

Pro tip: Allow cooling between welds to prevent warping (standard aluminium practice).

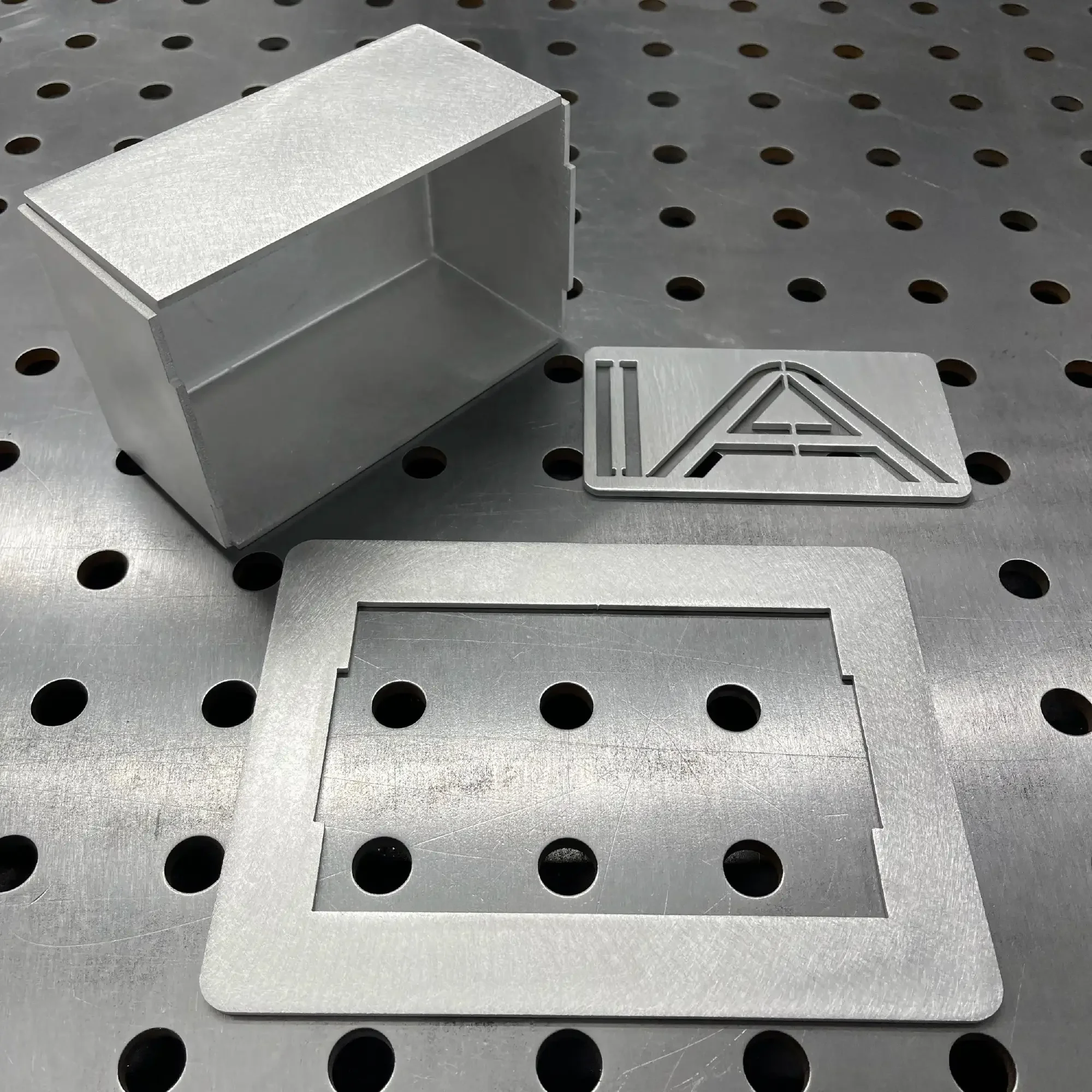

⚠️ Important Note — Heat Sink Required

A heat sink of at least 0.25” (6 mm) thickness must be used to prevent warping of the base flange during welding.

If you don’t have one, clamp the kit directly to a metal tabletop.

Example Heat Sink:

0.25” (6 mm) aluminium bar stock or any solid metal table surface.

Build precision, manage heat, and master box welds.

The IA-FAB Aluminium TIG Practice KIT-3 “Box It Up” is built to challenge and refine your control on closed and open-corner TIG joints. This precision laser-cut kit is designed for training on real-world aluminium box weld setups, giving you the chance to fine-tune your torch angle, filler rhythm, and distortion management.

Cut from 0.125” (3.2 mm) 5052-H32 aluminium sheet metal, each piece fits perfectly for repeatable practice and consistent setup. The “Box It Up” kit helps you dial in bead consistency and learn proper cooling control — crucial for aluminium TIG work.

Specs

Material: 0.125” (3.2 mm) 5052-H32 aluminium

Recommended filler: 3/32” 4043

Joints: Fillet, open corner

Focus: Box joint welding, tie-ins, distortion control, and fit-up accuracy

Pro tip: Allow cooling between welds to prevent warping (standard aluminium practice).

⚠️ Important Note — Heat Sink Required

A heat sink of at least 0.25” (6 mm) thickness must be used to prevent warping of the base flange during welding.

If you don’t have one, clamp the kit directly to a metal tabletop.

Example Heat Sink:

0.25” (6 mm) aluminium bar stock or any solid metal table surface.