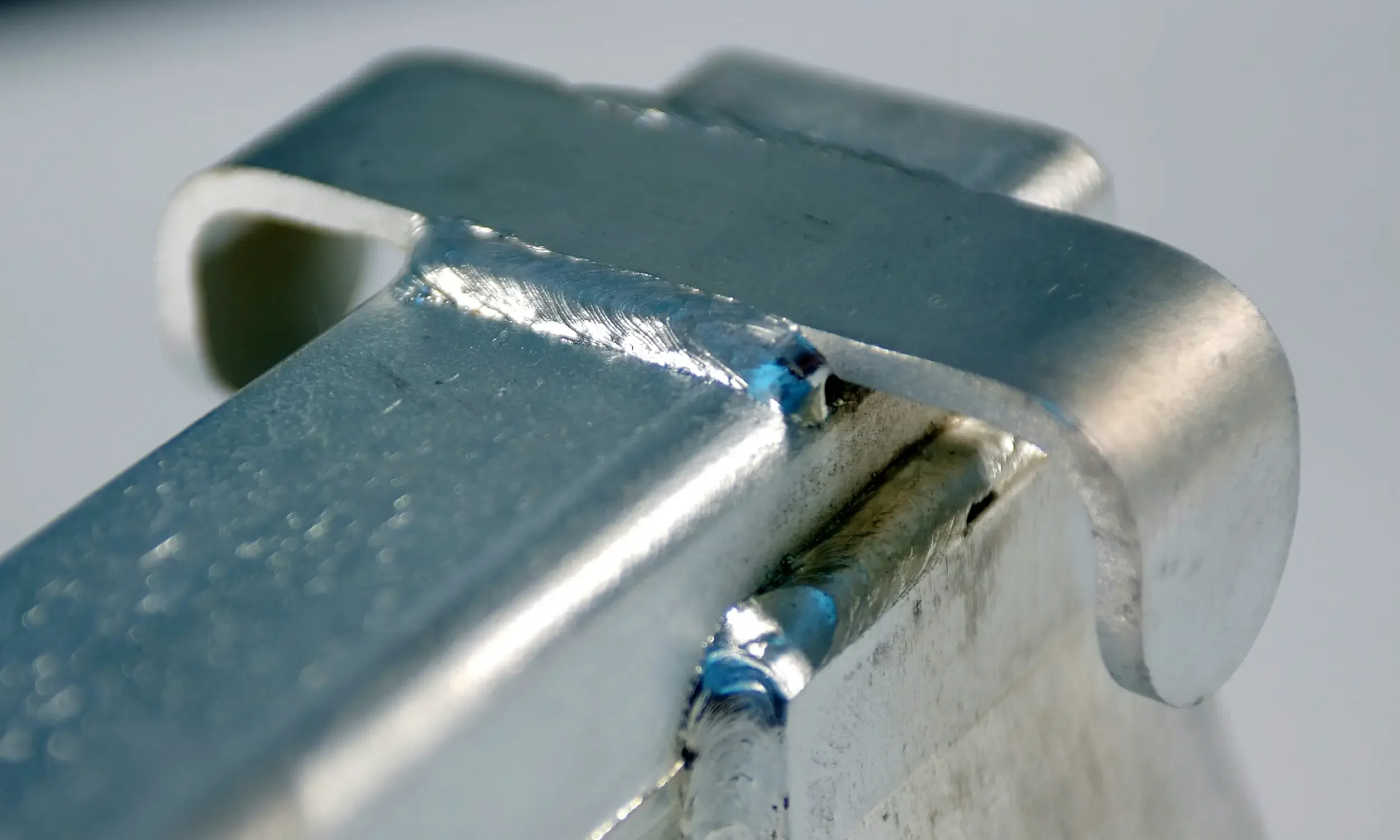

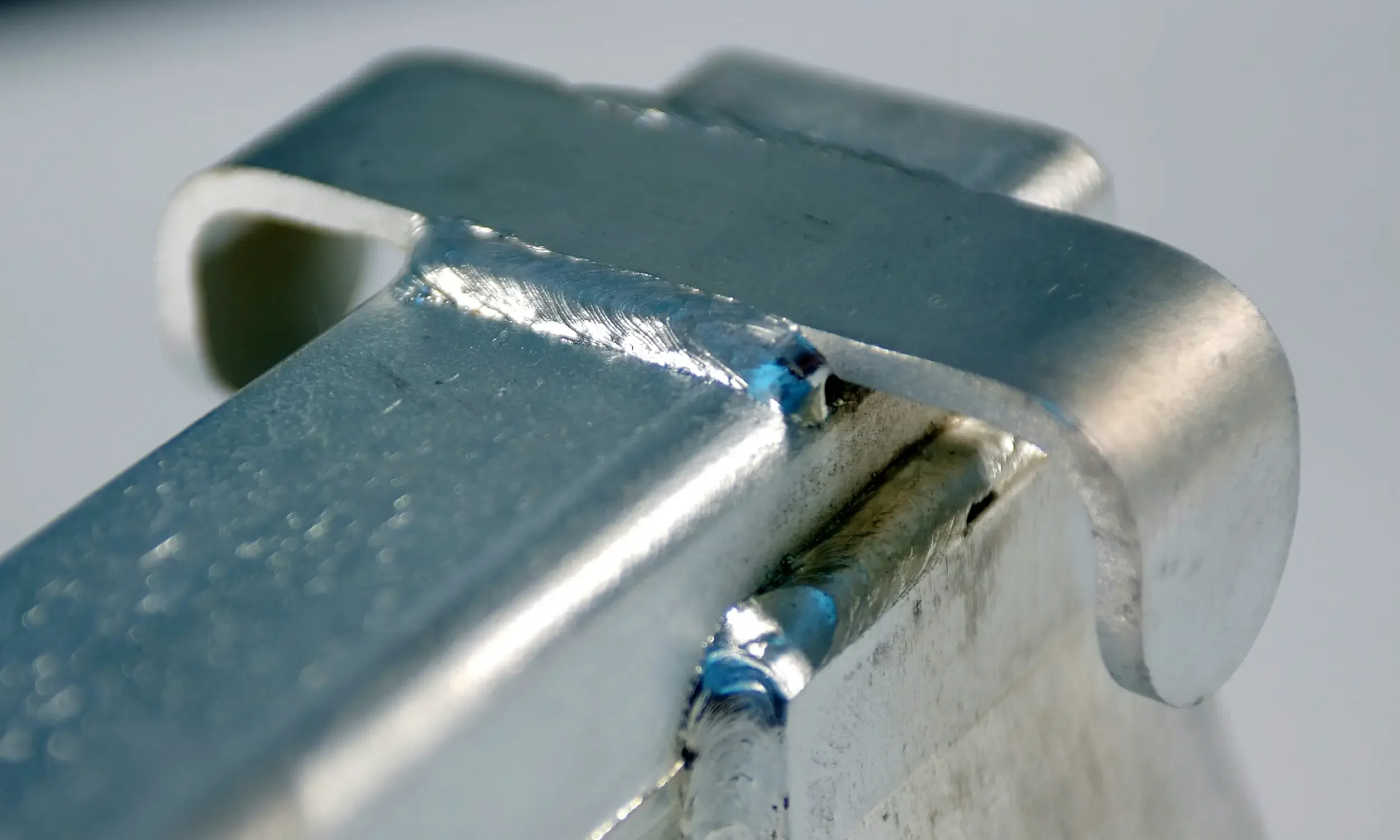

Precision TIG/MIG welding and small-batch metal fabrication for industrial and custom parts—done right, on time, to spec.

Welding & Fabrication

Capabilities

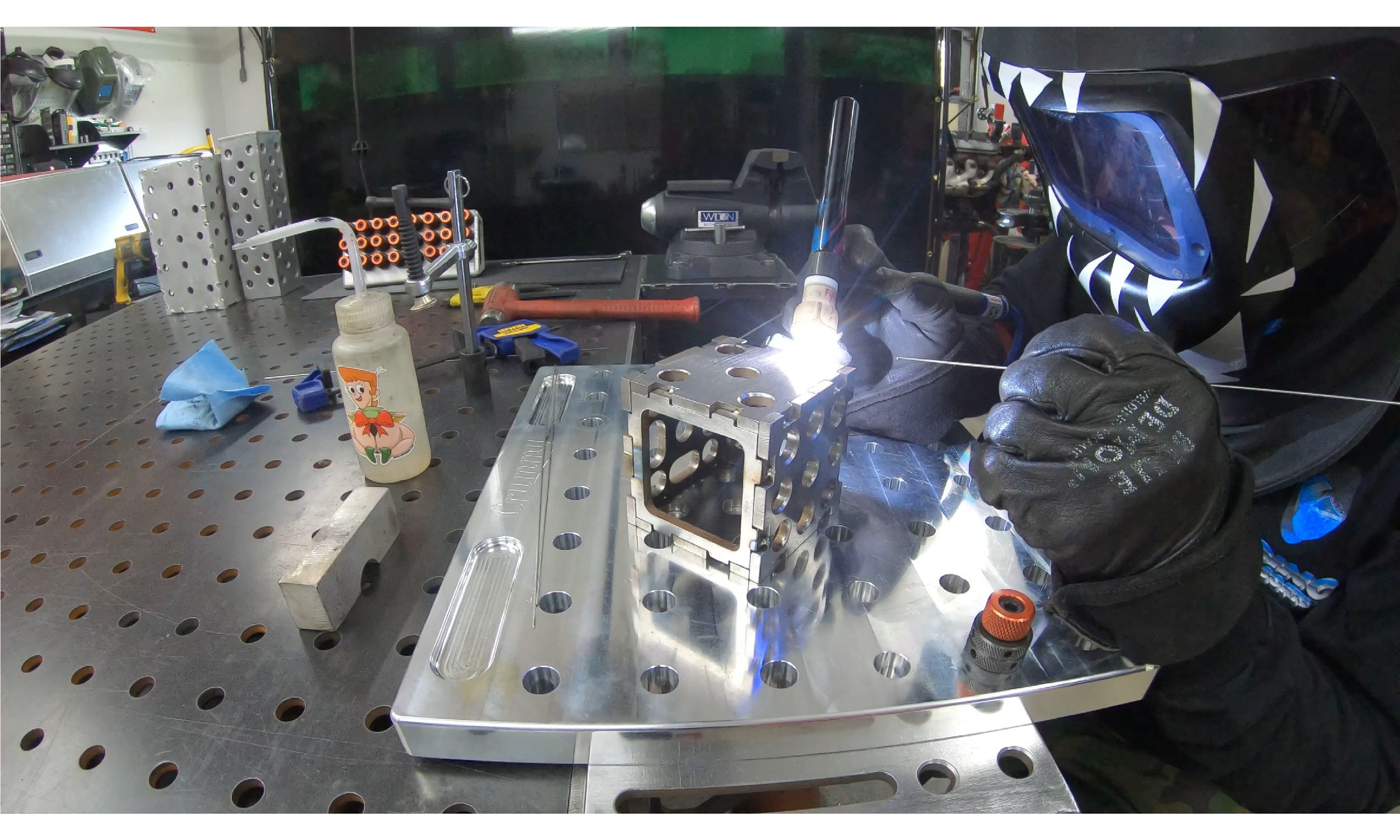

At IA-FAB, our welding and fabrication capabilities cover everything from precision TIG and MIG welding to full metal assemblies. We work with steel, stainless, and aluminum to produce prototypes, production parts, and industrial components—all built to spec, inspected, and delivered on time.

TIG & MIG: steel, stainless, aluminium

Sheet & plate fabrication

Tube/pipe welding & frames

Brackets, housings, guards, fixtures

Jigs and small assemblies

Our Process

Every project at IA-FAB follows a clear, repeatable workflow built for accuracy and speed. From the first drawing review to the final inspection, our team keeps communication open and quality at the forefront—so you always know where your job stands and when it will be delivered

Review drawings & requirements

DFM feedback (optional)

Quote & lead time

Fabrication & in-process QC

Finishing & assembly (if needed)

Final inspection & packing

Materials & Finishes

IA-FAB works with a wide range of metals and finishes to deliver parts that meet your strength, appearance, and durability requirements. Whether you need a one-off prototype or a small production run, we tailor every job to the right material and surface treatment for its intended use.

Materials:

Mild Steel, Stainless, Aluminium

Finishes:

Deburr, Media Blast, Powder Coat, Paint, Zinc

Industries Served

IA-FAB supports a diverse mix of industries that rely on precision, reliability, and short lead times. From manufacturers and marine contractors to R&D teams and local makers, our fabrication services adapt to each client’s technical and production needs.

Manufacturing & Automotive

Marine

Facilities

R&D

Makers

Quality & Compliance

Quality control is built into every stage of fabrication at IA-FAB. Our welders follow documented procedures, and every part is inspected for accuracy, strength, and finish before it leaves the shop. We maintain compliance with recognized AWS welding standards and provide inspection documentation or weld procedure specifications (WPS) upon request. Whether it’s a prototype or production run, we ensure every component meets your drawing and material requirements.

WPS available on request

Weld inspection and visual checks per job specification

Traceable lots available (on request)

Familiarity with standards: AWS D1.1 (Steel), AWS D1.2 (Aluminum)

In-process QC with calibrated tools and recorded measurements

Welding & Fabrication FAQs

We get a lot of questions from clients starting a new fabrication project — from file formats and materials to turnaround times and weld certification. Here are answers to some of the most common questions about our welding and fabrication services.

-

We can quote from PDFs, but for fabrication we prefer DXF, DWG, or STEP/IGES files. Clear, dimensioned drawings help us quote accurately and produce parts that meet your specifications. We can also sign an NDA if required before reviewing your files.

-

Lead times depend on complexity and finishing. Prototypes and small parts usually ship within 5–10 business days, while larger batches or multi-process builds may take 2–3 weeks. We’ll confirm lead time with every quote so you can plan production confidently.

-

Yes. We regularly handle single-part prototypes, test pieces, and small runs. Our workflow is flexible enough to support custom and low-volume projects with the same attention to detail as full production jobs.

-

We follow AWS D1.1 (Steel) and AWS D1.2 (Aluminum) standards. While we don’t issue third-party certifications by default, WPS (weld procedure specifications) and inspection reports can be provided on request for jobs that require documentation or traceability.

-

Most fabricated parts are held to ±0.25 mm (±0.010 in) unless otherwise specified. For critical features, tighter tolerances can be achieved depending on material and process. Every job includes in-process and final QC checks to verify accuracy.